Design elements are those things that make your space truly yours—indulge

At Fusion Custom Furniture and Design, LLC, we create wood and steel design elements to elevate your space. To us, design elements are those things that help create your space—they help set the 'mood'—though they are mostly decorative. That includes custom trim (and similar millwork) and wall cladding; it also includes things like handrails, stair treads, mantles, and pan racks. The possibilities are limited only by our imaginations. Let's create something amazing.

Browse some of our projects for inspiration and see if Fusion Custom Furniture and Design, LLC is right for your project.

Nestled in Shady Hollow, this home is a beautiful example of how coordinated interior finish work can make a space unique and sophisticated. A mix of design elements and millwork are found throughout.

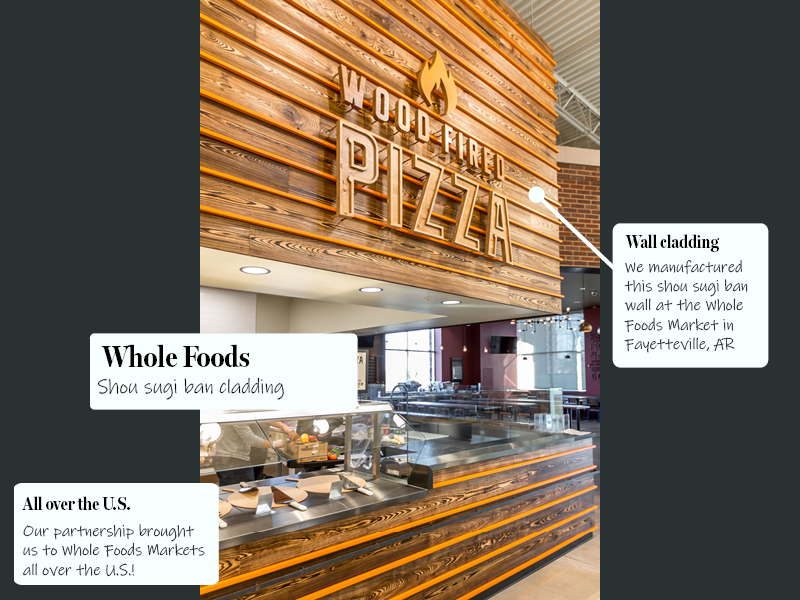

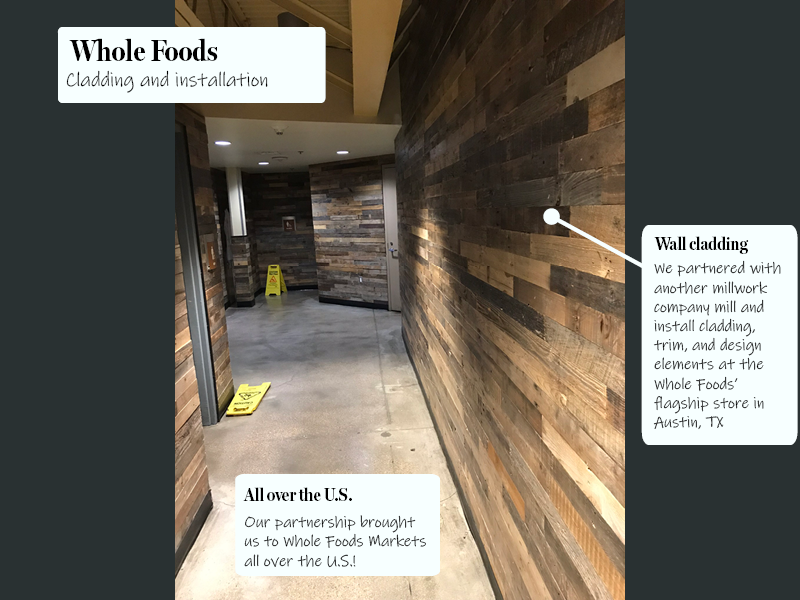

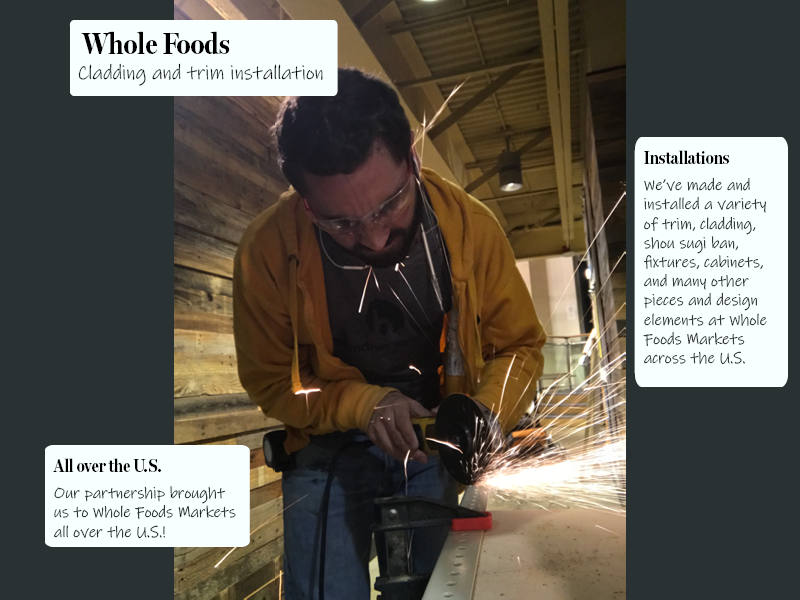

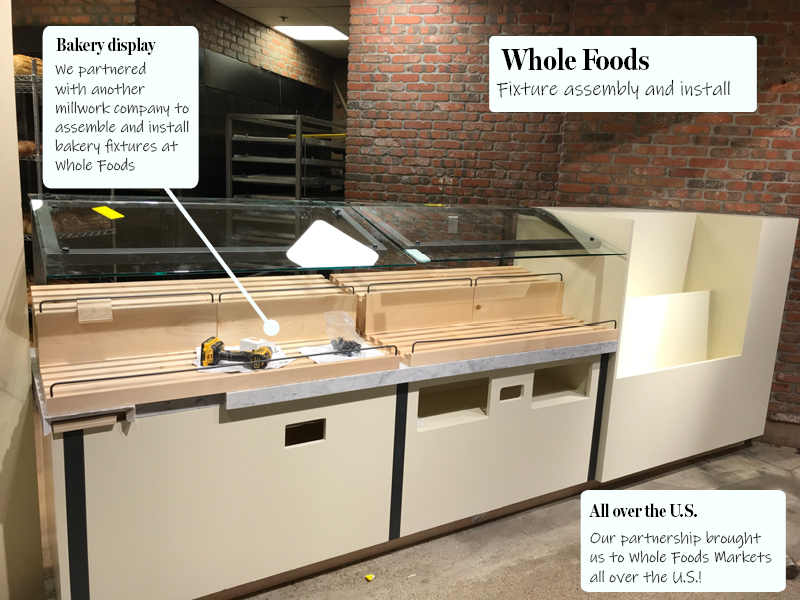

We've had the pleasure to work on several Whole Foods projects across the U.S. Whether we are creating their shou sugi ban or supporting their various design elements, we have been a trusted partner for years.

We played a leading role in the making of the custom liquor display, millwork, and trim around the Austin Proper in downtown Austin, Texas. Unique projects like this are tremendous collaborative efforts.

\Torchy's Taco is home to our personal favorite: the "trailer park" taco (be sure to get it 'trashy'!) They serve some of the tastiest tacos you will ever have. We helped to fabricate their 'hidden' door in Colorado.

This kitchen renovation called for patina'd steel beam cladding and a floating butcher-top counter. The zig and the zag in the header's path made for a tricky fabrication and installation.

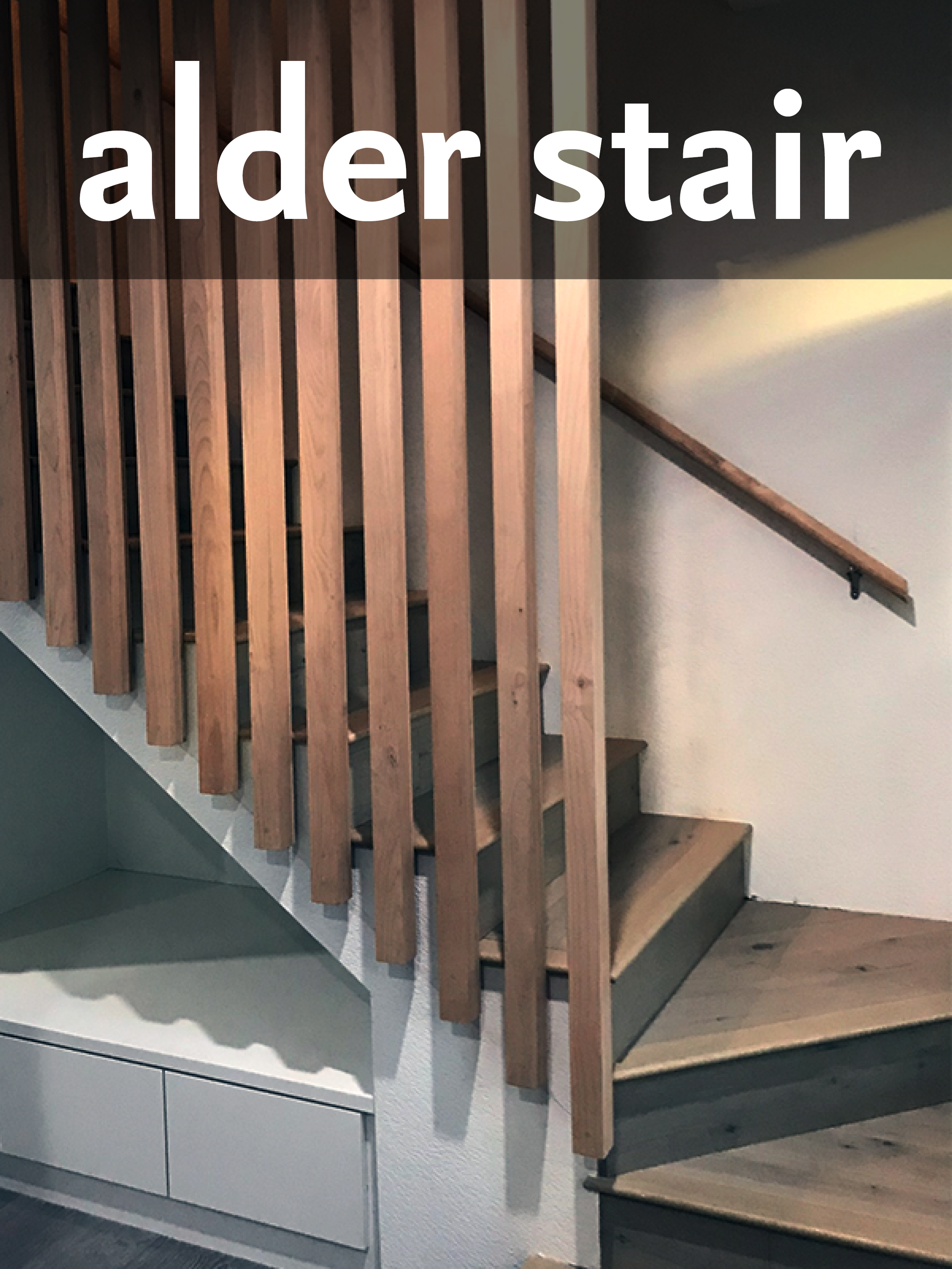

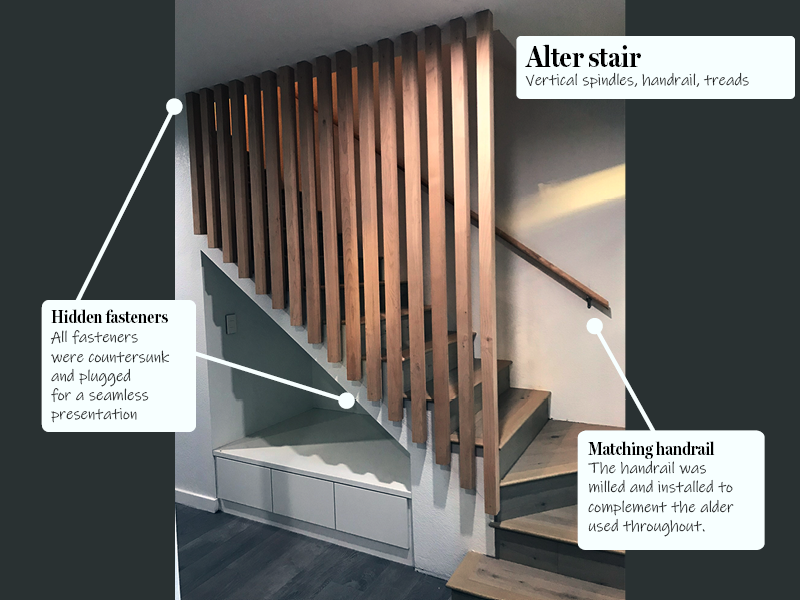

The design elements in this home's kitchen and entryway were milled of alder. We clad the kitchen's header and installed a vertical railing at the stair. We used hidden fasteners to keep the design elements sleek.

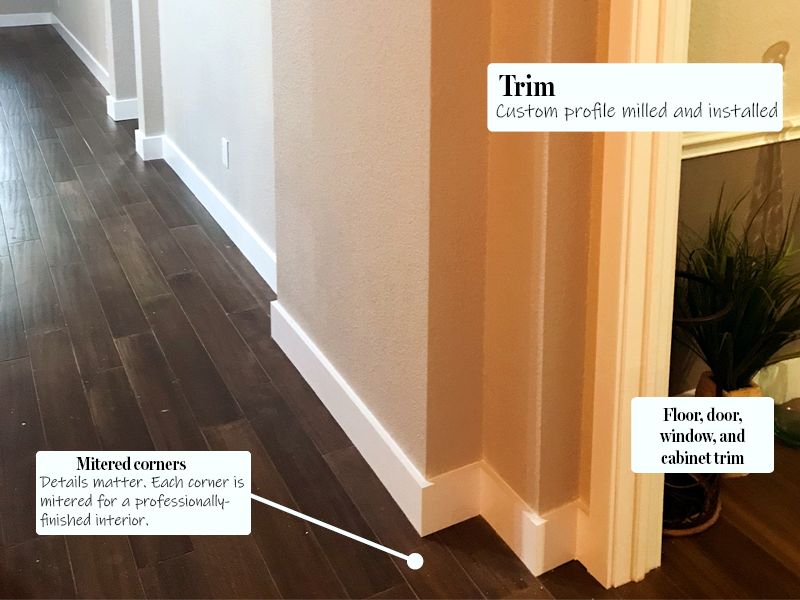

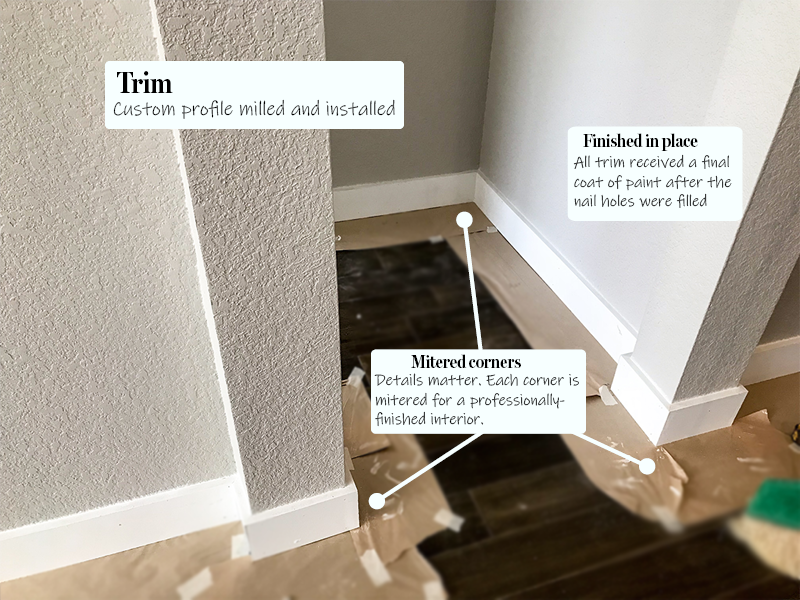

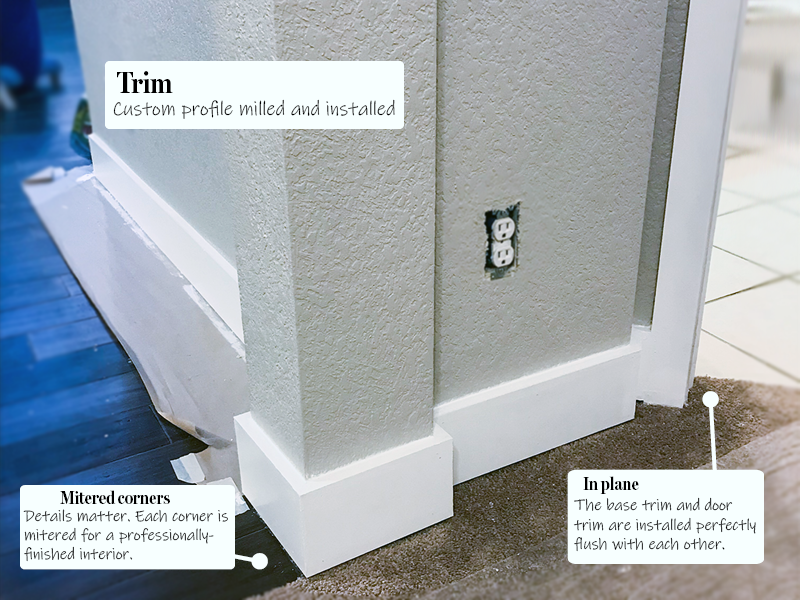

The base trim at the Shady Hollow house was custom milled for height and the true-square profile. Mitered corners abound in this home’s multi-dimensional layout. In addition, the base trim is perfectly in-plane with the door trim.

The trim was finished in place. We filled the fastener holes, caulked against the wall, and painted the trim. Each corner is mitered – inside and out – to create a beautiful presentation, no matter where you look.

The house has both square corners and unconventional angles. The base trim and door trim were installed to fall perfectly in plane with each other. Where they meet, the joints were finessed to create an absolutely seamless joint.

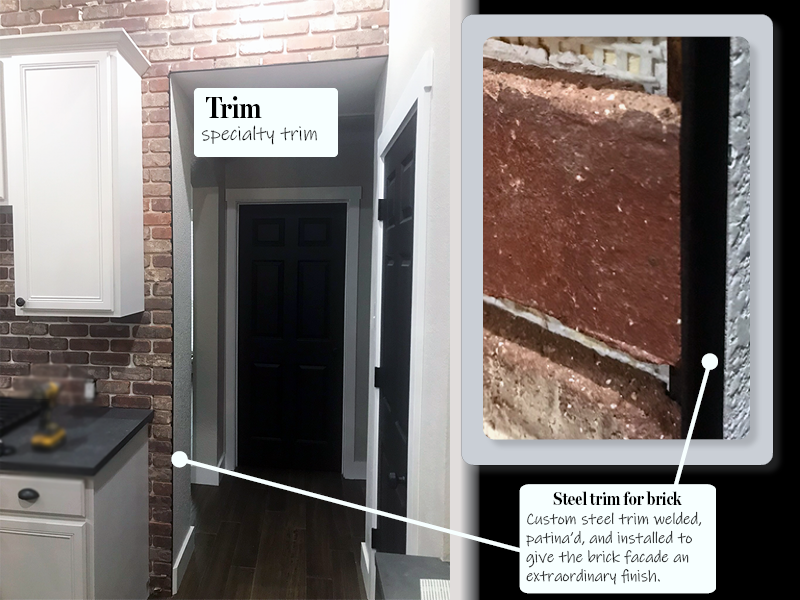

We fabricated a custom steel trim element for the kitchen’s brick tile facade. Made of ½” angle iron, we cut, welded, and patina’d the trim piece. The back of the brick tile is carved out so it lays flat against the wall.

We fabricated the kitchen island and the countertop at the Shady Hollow house. Flawless joinery on the island’s finished end and a professionally painted finish adds extra excellence to the home’s remodeled kitchen.

We fabricated the kitchen island’s top, matching the post’s cladding and mantel elsewhere in the house. The 2” thick butcher block top is finished with food-safe colorant and butcher block oil. It’s strong enough to chop on, but so beautiful that you won’t.

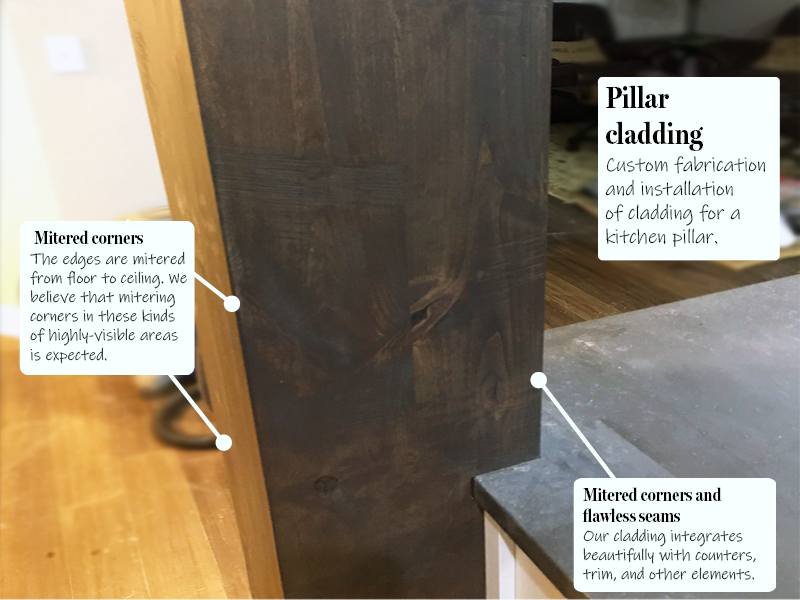

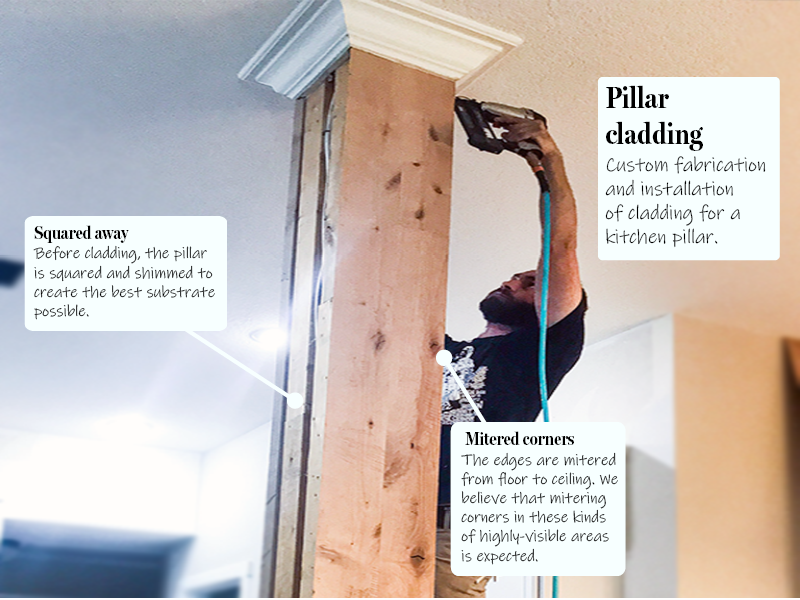

The post in the kitchen is an excellent example of our finish work where several elements converge. The post’s cladding intersects the peninsula cabinets and counter, and is finished to match the island's top.

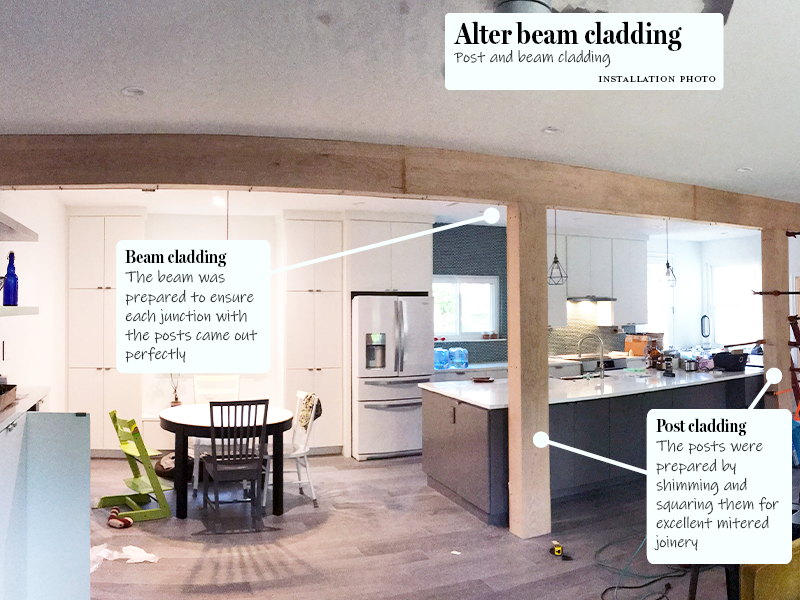

Before cladding, the post was shimmed and squared to allow for flawless mitered corners, from floor to ceiling. The cladding was distressed to match the floor’s texture and finished in place to match the island’s top and the fireplace mantel.

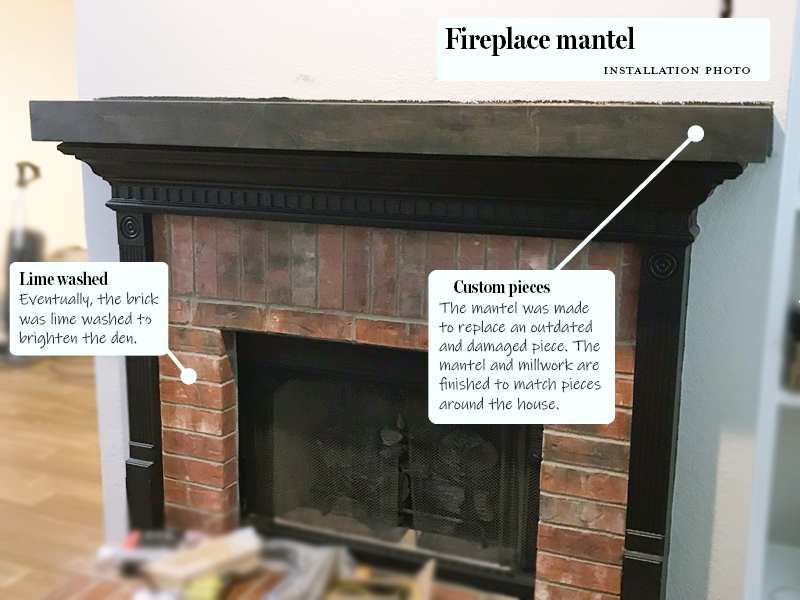

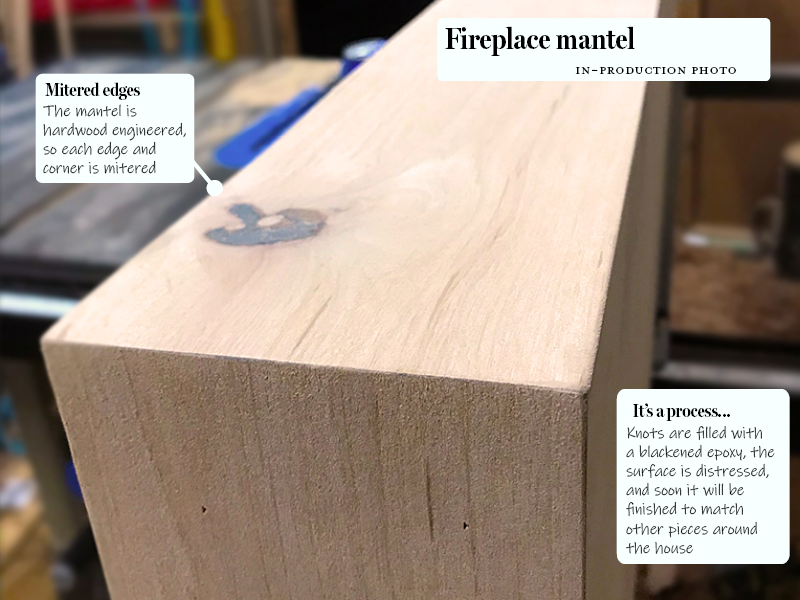

The Shady Hollow house has a mixture of old and new. The fluted mantel legs, shelf crown, and cornice were painted to match the new color scheme and the mantel was fabricated to match the island top and kitchen post cladding.

Knots and defects in the mantle were filled with blackened epoxy. The mantel itself is hardwood-engineered – it is a ½” thick hardwood skin over a multi-ply baltic birch substrate frame. It is incredibly strong and stable.

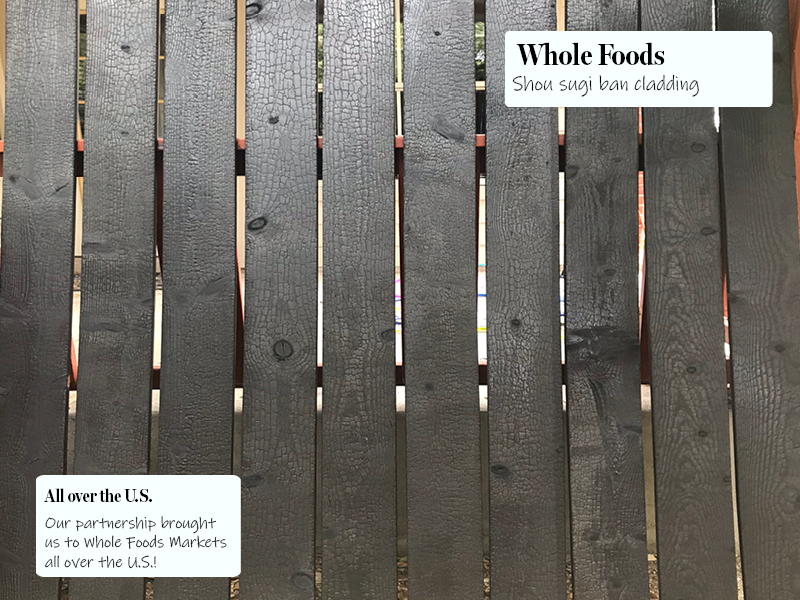

Fusion Custom Furniture and Design, LLC has been making shou sugi ban for Whole Foods Markets across the United States since 2015. Our custom made shou sugi ban is milled, burned, brushed, colored, and finished in the Fusion shop.

We are proud to have worked with Whole Foods in several of their stores across the U.S. Here, we installed custom wall cladding, steel trim, and other design elements in the flagship store, located in downtown Austin.

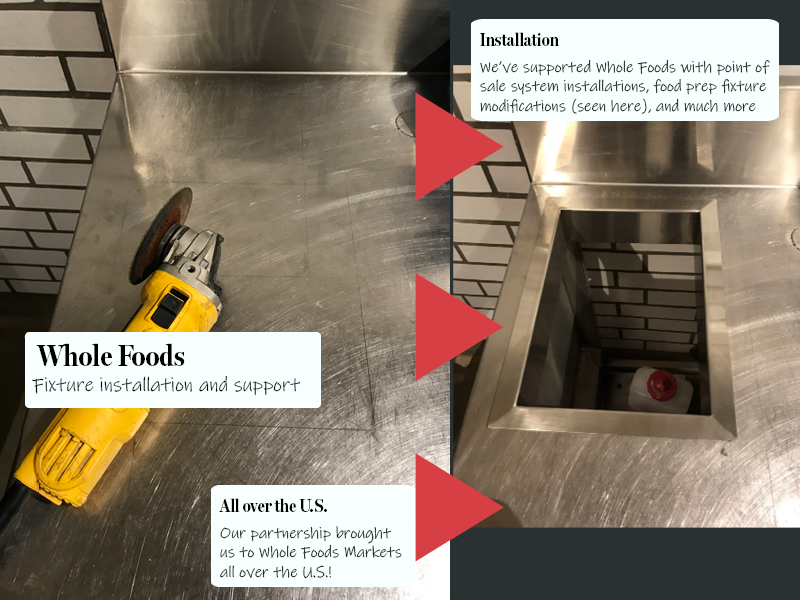

At Fusion Custom Furniture and Design, LLC, we work with wood and steel to create beautiful finish work for Whole Foods’ store interiors. Our installations and millwork can be found in stores across the U.S.

Whether we are fabricating your fixtures or simply installing them, trust Fusion Custom Furniture and Design, LLC to meet and exceed your expectations! Here, we finished installing the bakery fixtures at Whole Foods.

Fusion Custom Furniture and Design, LLC made the shou sugi ban used to clad the salad bar at the Whole Foods cafeteria. The custom color and the food-safe finish help to make our material a beautiful (and safe!) addition to the food court.

Let our experience in food service and hospitality be an asset to your project! We are experts in customizing your workspace to make it work for you. Here, we installed a waste drop through (and shelf) to a Whole Foods kitchen.

Our shou sugi ban comes in a variety of finishes. Here, a ‘gator burn’ shou sugi ban creates a unique texture. For this finish, we use a specially-treated material that holds the burn without crumbling apart or giving off messy soot when touched.

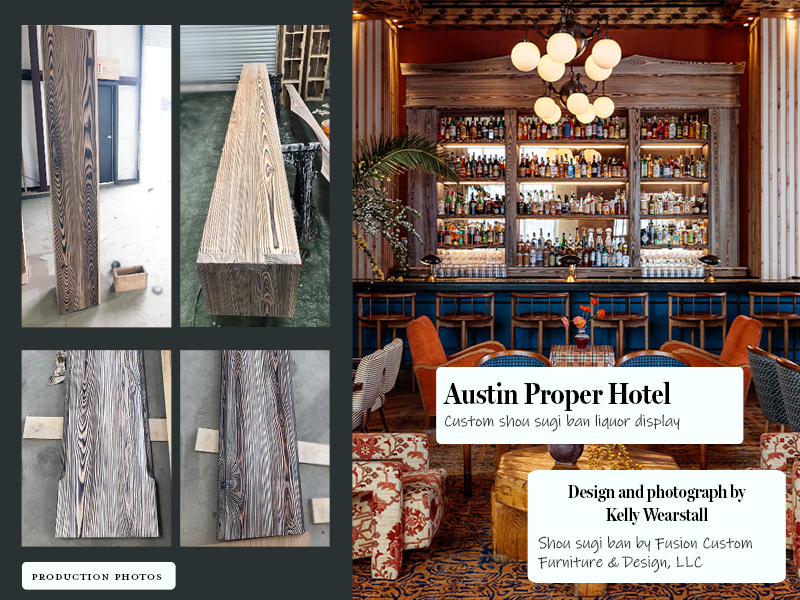

The bar at the Austin Proper Hotel in Austin, Texas is made from shou sugi ban by Fusion Custom Furniture and Design, LLC. Our partnership in this project was in fabricating the furniture and millwork around the hotel.

Intricate details – like the cornice’s dovetail joint or the pillar's scalloped edge – make for a challenging (but rewarding!) project. The mitered crown molding tops off the one-of-a-kind liquor display.

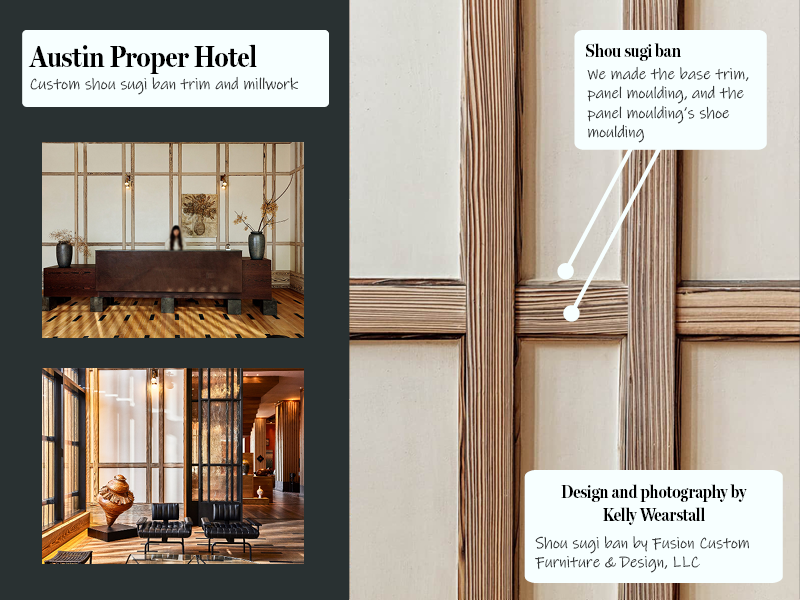

From floor to ceiling, our custom millwork package can be found throughout the Austin Proper Hotel. We manufactured the shou sugi ban for the base trim, panel molding, and shoe molding used in the reception area.

The wall detail — designed by Kelly Wearstall — includes panel molding, trimmed further with ½” square shoe molding. A unique feature of this project was in finishing multiple faces of material with shou sugi ban.

We made the shou sugi ban for Torchy’s Taco restaurant in Colorado Springs, CO. Made of cypress wood, the skin for the door was milled and grain-matched with the wall cladding to be nearly invisible once installed.

The restaurant loved our material! So much so that they asked us to make extra material and deliver it to the restaurant. We are always happy to go above and beyond to make your project even better – how can we help you?

The shou sugi ban for Torchy’s Taco is custom colored ‘million dollar red’. We manufactured enough shou sugi ban to clad the bar wall, lavatory hallway, and a pony wall near the point of sale counter.

Shou sugi ban is a traditional Japanese style of burning wood. Our shou sugi ban is often made of cypress, like the material we used at Torchy’s Taco. We can mill custom profiles and finish material with a color of your choice.

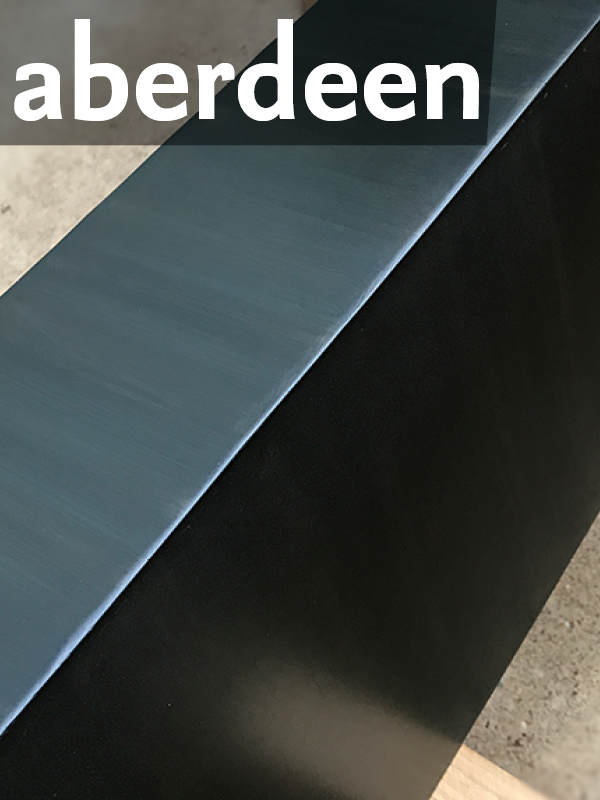

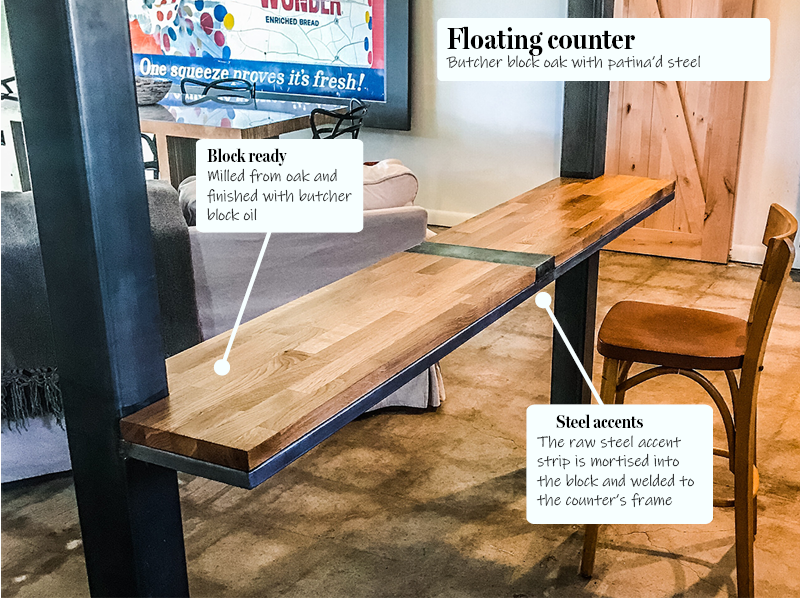

The Aberdeen floating counter features an oak butcher block top with a patina’d steel strap accent. We fabricated and welded the counter’s frame to the steel posts and fabricated the butcher block top.

The patina’d steel strap is mortised into the white oak butcher block top. Though the strap is welded to the counter’s frame, the wood top can still be completely removed for cleaning. Our butcher block tops are finger jointed for strength and stability.

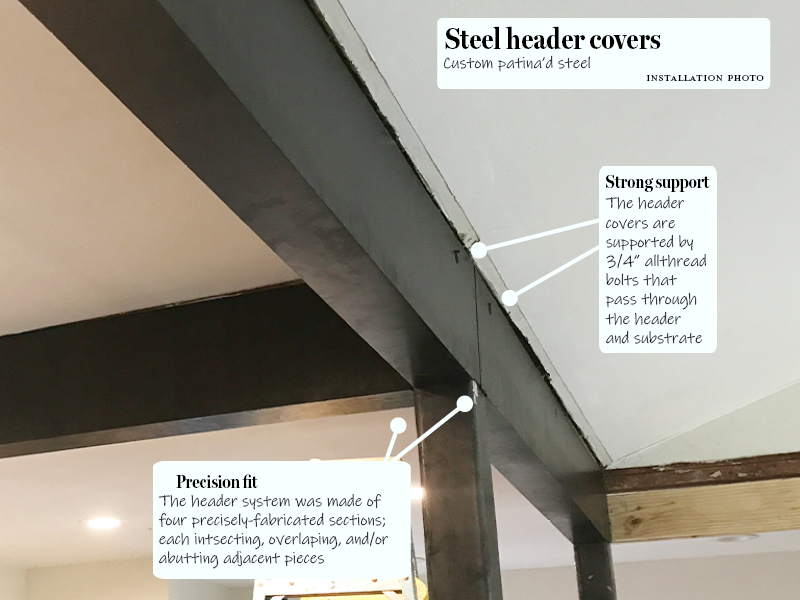

We designed, fabricated, and installed the patina’d steel header covers in the Aberdeen house remodel. The header system is made of four individual pieces that fit together like a very large and heavy puzzle.

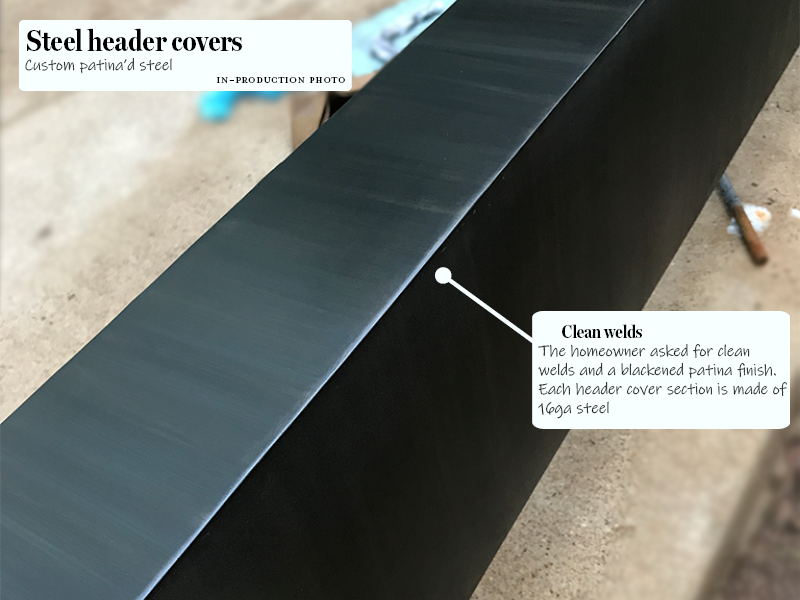

Each header piece was cut, welded, and patina’d to a beautiful finish. A consistent finishing technique creates a slightly-streaked finish in black patina. Our welds are finished to a crisp edge – like they’re not even there.

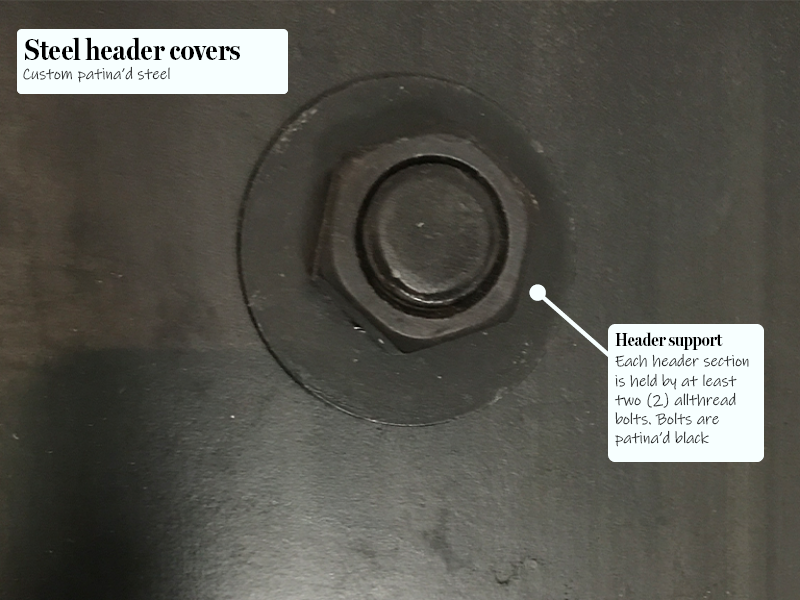

The header system is made of four individual pieces that fit together like a very large and heavy puzzle. The seams and joints are designed for a snug fit. The headers are fastened to the wood substrate with ¾” bolts.

The headers are fastened to the wood substrate with ¾” bolts. The bolts, washers, and nuts are patina’d to match the header’s finish. Each bolt passes all the way through the wood substrate that the header covers.

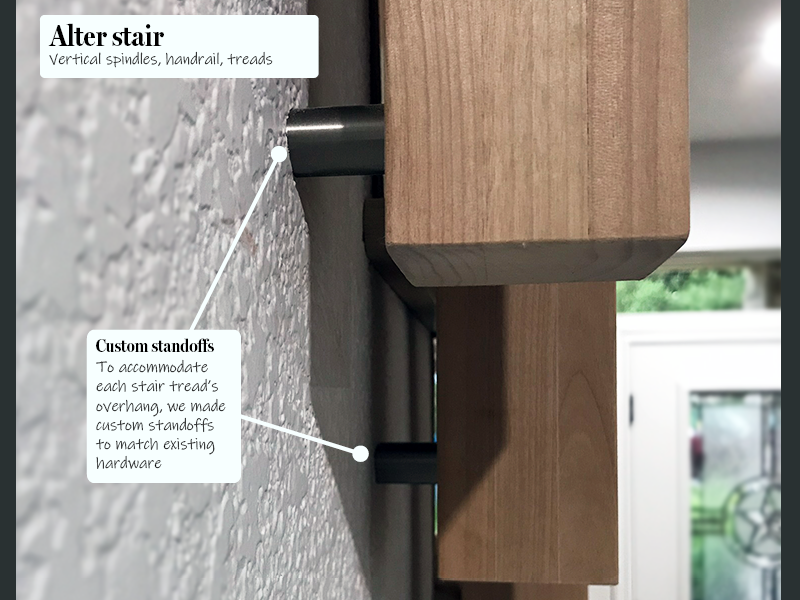

These homeowners wanted to make a statement in their home’s entry—they certainly did. The newel posts and handrail were milled of alder and installed by Fusion Custom Furniture and Design, LLC. Don't settle for less than excellence.

The nosing of stair treads usually overhangs the riser and the wall to the side, making it necessary to install standoffs so the newel posts are perfectly plumb. In the “alder house” we made custom standoffs to manage the job.

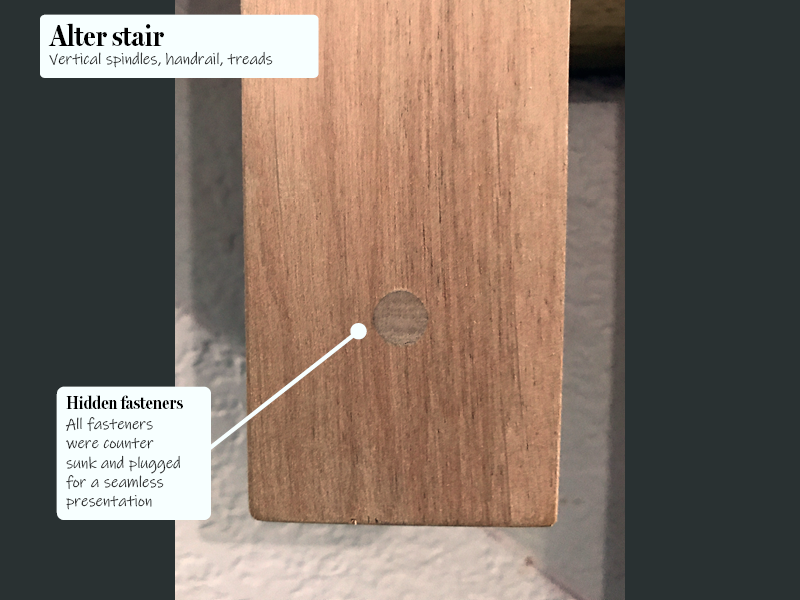

Nothing says “I was screwed in place” like visible fastener heads. To create a seamless presentation, we milled custom wood plugs to fill the holes left by countersinking the newel post’s fasteners.

To match our design elements elsewhere, we clad the header and posts in the kitchen with alder. The substrates were made square with shims so our joinery aligned perfectly. All fasteners are hidden, as with the stairs.